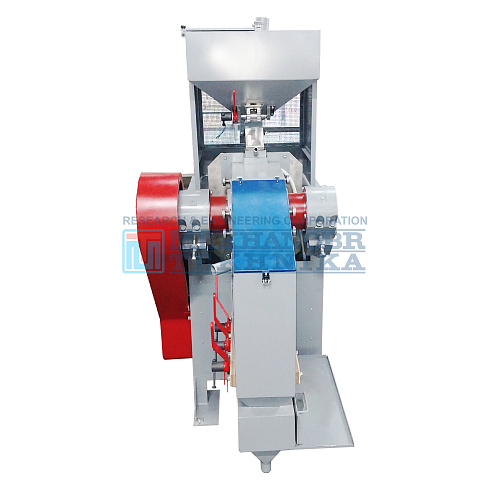

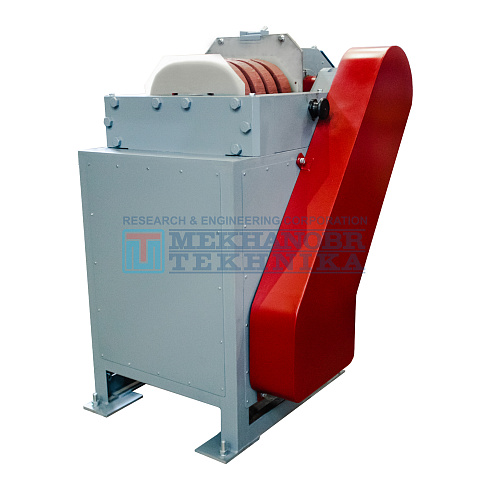

EVS-28/9 electromagnetic roll separator For dry separation of weakly magnetic ores and nonferrous materials into magnetic and nonmagnetic fractions in continuous mode.

Characteristics:

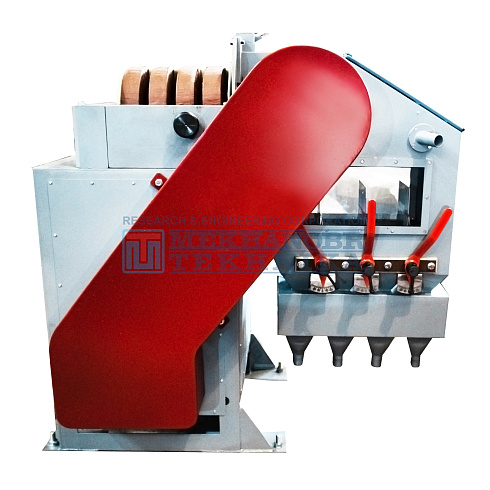

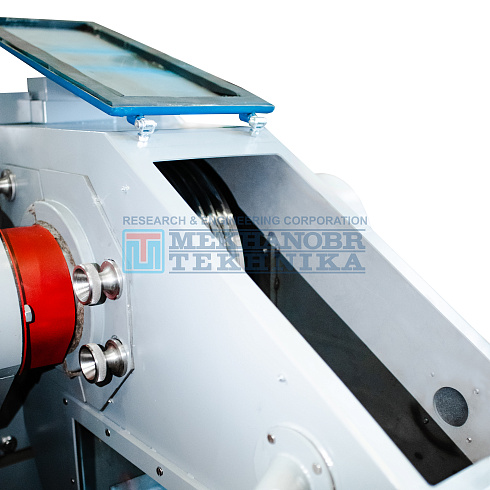

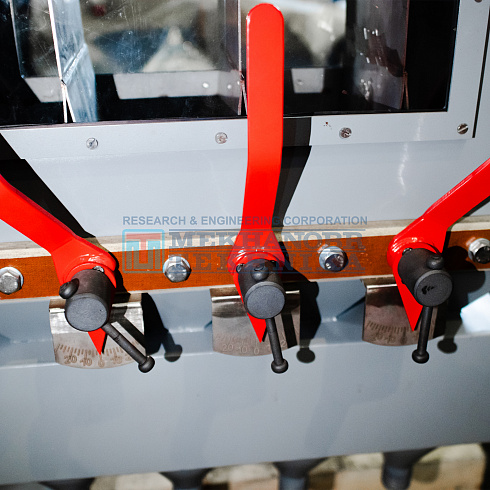

Adjustments can be made to the composition of the separated products in the compartments by selecting the magnetic field intensity in the work zone, roller rotation frequency, and also by turning the tank partitions (gate valves) that form the compartments. Tank side walls have glass windows to observe the separation process. Additional illumination is also installed inside. An orifice is installed on one of the side walls for connection with the exhaust system of ventilation during work with dust-forming materials. A sampler is installed under the outlet orifices of the tank to collect samples of the separated material.

Operating principle:

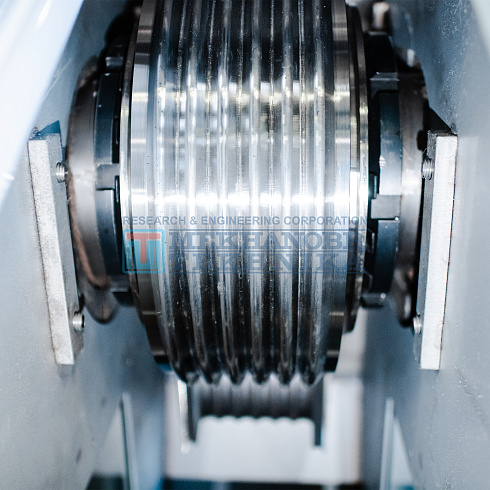

The material to be separated (preliminary dried) is supplied to the feeder hopper, and then flows to the working area via the gate valve along the inclined and vertical trays. When the material flows via the working area, the magnetic particles are attracted to the rotating roll teeth and flown out to the area with the weakened magnetic field where they are detached from the roll and flow to the bath compartments. The particles with higher magnetic susceptibility go to the compartments more remote the roll, and the nonmagnetic particles fall into the nearer compartment.

The separated product content in the compartments can be regulated by changing the magnetic field intensity in the working area, roll rotation frequency, and also by turning the bath partitions that form the compartments.

Delivery set:

- Separator assy

- operating console.

For purchasing the equipment or for more detailed information, don’t hesitate to contact us +7 (812) 331-02-43.