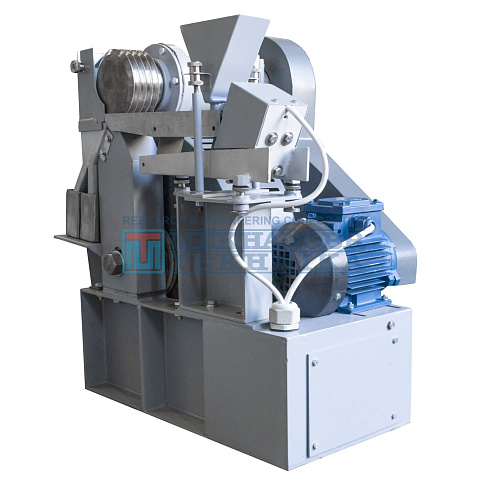

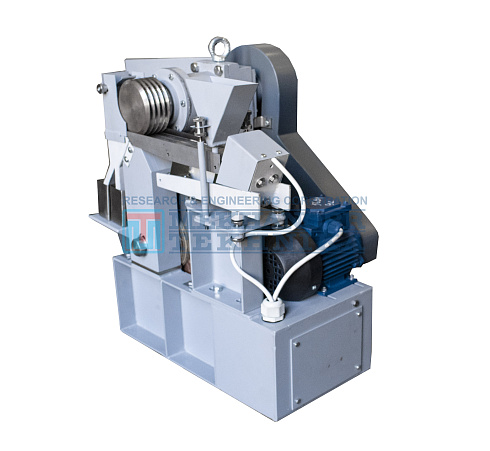

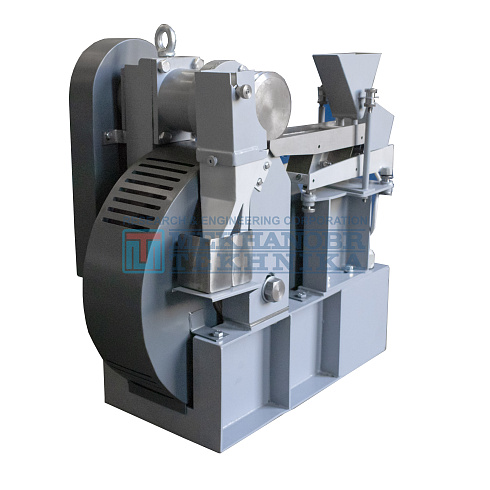

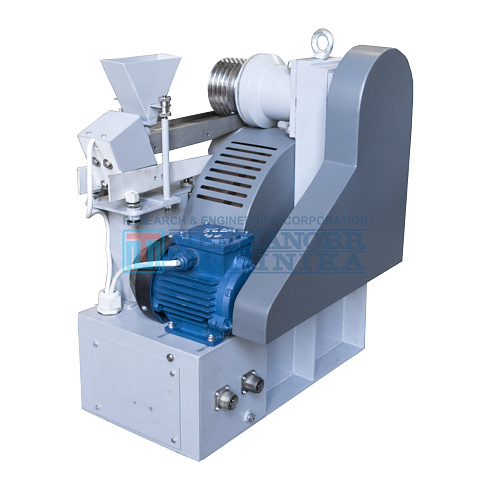

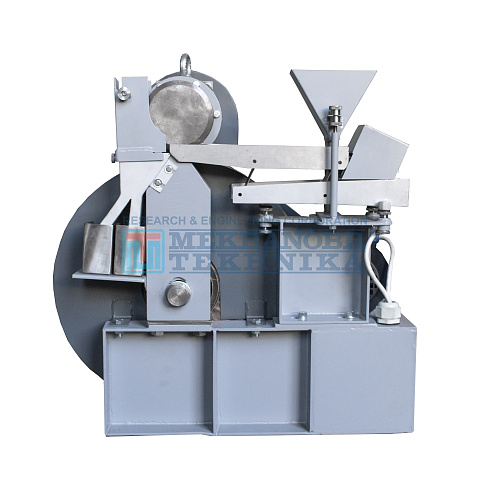

EVS-10/5 electromagnetic roll separator

The separator is designed for dry separation of weakly magnetic ores and materials into magnetic and nonmagnetic components.

Characteristics:

The separators are constructed to allow for their usage as analyzers under laboratory conditions, in metallurgic plants and in other branches of industry.

Adjustments can be made to the composition of the separated products by selecting the feed speed of the vibratory feeder, magnetic field intensity and position of the feed launder in the work zone.

Operating principle:

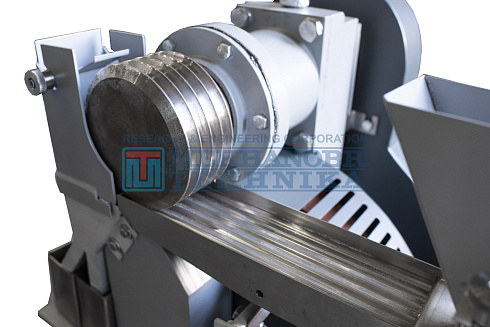

The material to be separated is poured into the hopper and then supplied to the working area along the vibrating feeder tray. The magnetic particles are attracted here to the rotating roll teeth surface and flown out to the area with the weakened magnetic field where they are detached from the roll teeth and flow to the inlet chute compartment “a”. The nonmagnetic particles fall from the tray to the compartment “b”.

The separated product content can be regulated by changing the magnetic field intensity in the working area, rate of material fed by vibrating feeder and tray position in the working area.

Depending on the degree of magnetic susceptibility of the material and particle size distribution, the separated product quality can be regulated by changing the magnetic field induction in the working area, rate of material fed by vibrating feeder, clearance between the pole and the roll, and tray position in the working area.

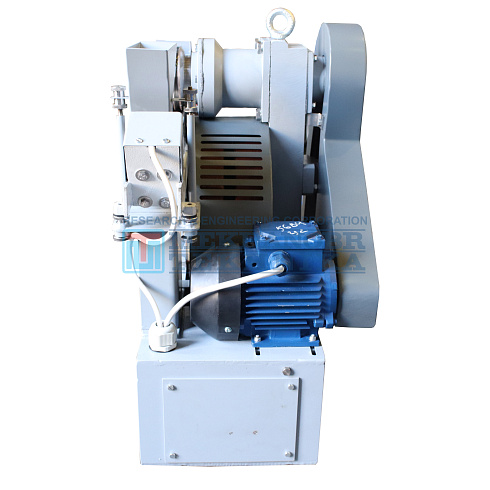

Delivery set:

- Separator assy

- operating console.

For purchasing the equipment or for more detailed information, don’t hesitate to contact us +7 (812) 331-02-43.