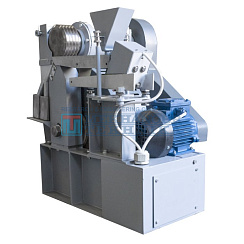

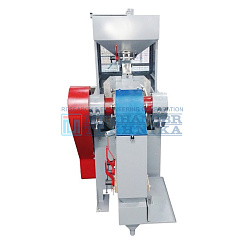

Magnetic separators

Magnetic separators

The magnetic concentration processes that are based on differences of magnetic properties of the separated components are widely used for concentration ferrous and nonferrous ores, as well as many other materials.

Purpose and operating principle of magnetic separator:

The magnetic separators are used for separating the magnetic and weakly magnetic components and admixtures from various kinds of natural solid and technogenic materials (ores, construction and abrasive materials, industrial waste, and etc.).

The magnetic field is created in the working area of the magnetic and electromagnetic separator with the help of constant magnets or electromagnets, and when freely passing this working area , the motion trajectory of magnetic and (or) weakly magnetic particles differs from the motion trajectory of nonmagnetic particles. Due to this, the particles with various magnetic susceptibility are collected in separate receiving tanks.

The magnetic separation can be performed both in water environment and in the dry process. The dry and wet induced magnetic separators differ by design.

Advantages of magnetic separators:

- production of high-quality concentrates with high recovery of useful component;

- environmentally friendly process;

- high selectivity and versatility;

- low energy consumption.

Currently, the Research and Engineering Corporation “Mekhanobr Tekhnika” supplies to the domestic and foreign markets the magnetic separators of various types: EVS, EVS-V, EVM, PBSTs, EBM, PBM, ERM. The separators are regularly upgraded.

REC Mekhanobr Tekhnika offers the following services for the customers:

- researches for sample preparation characteristics of the customer’s material, determination;

- production of the required process parameters of separation with their guaranteed validation after separator introduction at the customer’s enterprise;

- providing of recommendations on determination of the optimum separator type or updating the design as per the customer’s specifications;

- designer’s supervision of the separator manufacture, participation in supervised installation and commissioning (if necessary), maintenance staff training.

For purchasing of the equipment you are interested in or for more detailed information, please contact us by phone +7 (812) 331-02-43.