Samplers

The performance of the mining companies considerably depends on reliability and accuracy of information on chemical composition and moisture content of the products transported in the form of pulp, that is the minerals and water mixture, between the process operations, or going out of the concentrating stage. For the pulp systematic analysis, further timely control of process mode depending on the ore, concentrate and tails content, as well as for making the material balance of the processed raw material, the samplers are used. They are the mechanical devices providing for systematic sampling from the process flows.

Features of samplers

The samplers by "Mekhanobr-Tekhnika" differ by their purpose and design depending on the scope of application, namely:

- For sampling of the pulp contained minerals for chemical analyses. Based on these analyses, the material balance of the key components extracted by the company is made.

- For systematic monitoring and control of the ore concentration process.

Scope of application of samplers

The samplers are used at the concentration plants in the test technologies of the concentrate, interim and tails suspensions (pulps).

The pulp is a process mix of the ground minerals with the water at the ratio of 1:2 to 1:6 (depending on the kind of the process). This basic condition of the raw material prepared for concentration at the ferrous and nonferrous ore, as well as mining and chemical raw materials processing facilities. The size of the mineral particle fragments can be also different - from the first tens of micron to 2 mm.

Our solutions

The samplers supplied by Mekhanobr Tekhnika function as :

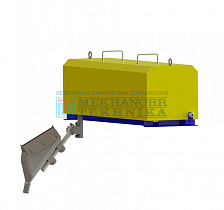

- 66-ОPG apparatuses - sampling and sample preparation for the raw material chemical analysis;

- 63-ОP apparatuses - sampling for automated production control.

Sampling with the first option of the equipment is performed with the blade-type bucket with the adjustable gripping width from 2 to 35 mm. Its movement covers the entire section of the raw material flow, that is why the design provides for sample reliability and representativity. The blade speed is selected so that to exclude the large pulp fragments to be thrown away. Number of cutoffs within a hour is adjusted within 1 - 360.

The second option of the equipment (63-ОP) is fitted with the submersible intake device of cylindrical form. The intake frequency is higher than that of the first option, the sample volume can be efficiently split Using this device is most reasonable in the automatic production control systems of the concentration plants.

How to buy the sampler?

For the sampler price, please contact our manager by phone or the application form given on the site. For technical and commercial information, please call by phone or make an application on the site.

For the types of the produced samplers, spare parts for them, as well as the list of other equipment produced by the company, please see the supplier’s catalogue.

For purchasing the equipment or for more detailed information, don’t hesitate to contact us +7 (812) 331-02-42.

REC Mekhanobr Tekhnika reserves the right to change the equipment specifications.