Purpose:

The mill is designed for fine and wet grinding of different ore samples and non-ore materials (minerals, ore, allows, chemicals, glass, ceramic, parts of plants, soil, sewage sludge etc.) with removable shells (metallic and ceramic) in a periodic mode.

Characteristic features:

The mill can be used for a material mixing.

Operating principle:

The mill is a periodic operation device.

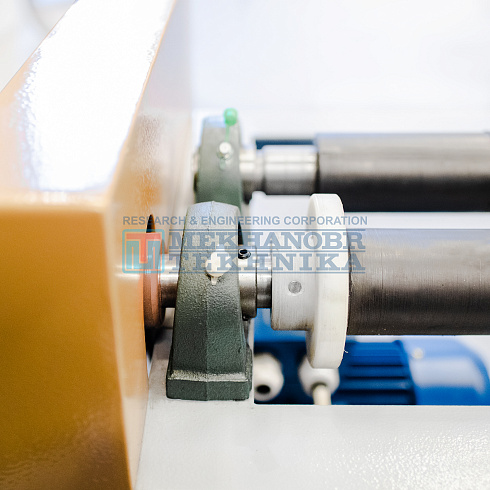

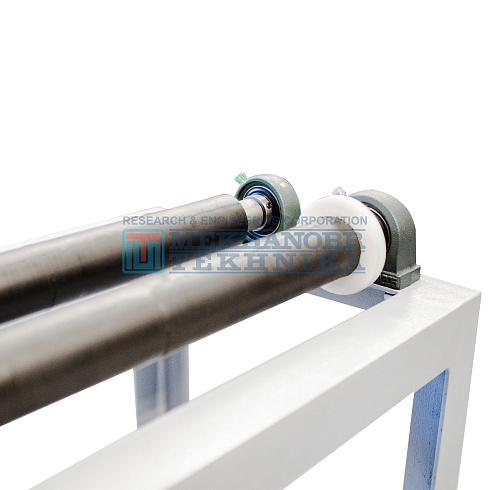

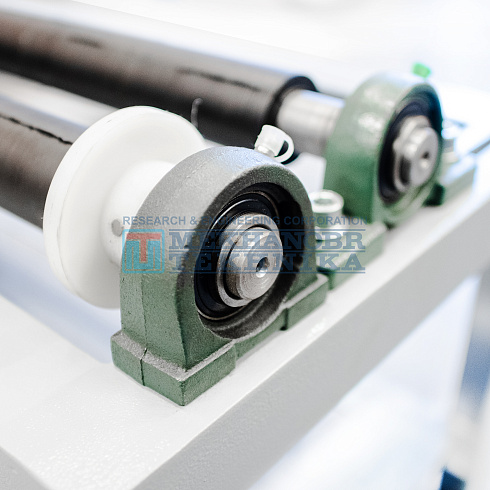

An operating part of the mill is a shell with cap. The shell set on rubber-covered shafts. Shafts are mounted on frame in roller bearing units.

The driving shaft is connected to the motor by a V-belt drive. The shaft can move along the frame for reducing the distance between rollers. The shaft is lined by a rubber sleeve. The V-belt drive is covered by a cover. A shell is filled with a material and balls. The material is crushed by attritioning and percussive effect of balls.

Operating console using with thyristor frequency converter allows to change a rotation frequency of the shell.

Delivery set:

The drive of the shell mill (rolgang).

Additional equipment:

The shell, the set of balls, the operating console.

For purchasing the equipment or for more detailed information, don’t hesitate to contact us +7 (812) 331-02-43.